For this project, I was assigned to model a moving mechanism in Solidworks and then fabricate it using the resources available at UW-Madison. I chose to adapt a set of blueprints from Elmer’s Tiny Engines, then build it in the UW-Madison TEAM Lab.

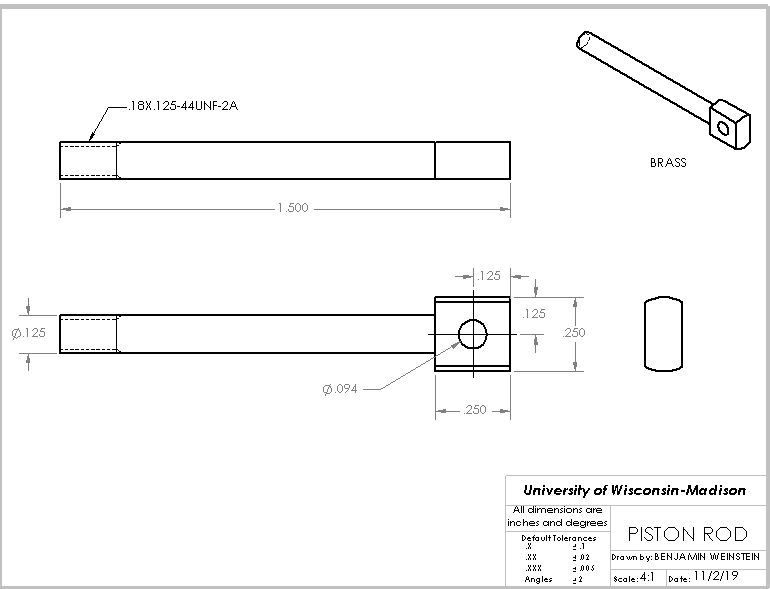

My Solidworks model was accurate to the plans, and I also created drawings to go along with each part.

Once the engine was fully modeled in Solidworks, it was time to fabricate it. This was the most extensive machining work I had ever done, and it took 30+ hours of lathe and mill work to create each part from stock. Significant thanks is owed to the UW-Madison TEAM Lab staff for guiding me in this process. Below are pictures of in-progress parts.

Once the parts were complete, I had to assemble the model. It was here that I ran into a problem– everything was manufactured to the plans, but the piston was not able to complete a full stroke and rotate the flywheel. After consulting with TEAM Lab staff for advice, I ended up reaming out the cylinder another two thousandths and drilling another 5 thousandths deeper. This provided enough clearance, and the engine worked properly. From this, I learned that projects aren’t guaranteed to work just because they work in Solidworks.